One topic that is sure to spark debate amongst pilots and A&P’s alike is whether or not it is acceptable to operate an aircraft engine lean of the peak exhaust gas temperature (EGT). Historically, the prevailing wisdom was that operating rich of peak (ROP) EGT was optimal for preventing engine detonation, while some point out that operating that way unnecessarily increased fuel consumption.

So, is operating an aircraft engine lean of peak harmful?

Operating an aircraft engine lean of peak EGT’s is not harmful as long as the limitations contained in the pilot’s operating handbook and the engine’s operator’s manual are followed. Operating lean of peak can greatly reduce fuel consumption while minimally impacting engine performance.

Lean of peak (LOP) operations can, in some aircraft/engine combinations reduce fuel consumption by up to 20% with only a 5% loss in performance as compared to peak EGT operations.

Even so, there are techniques and operating considerations that the pilot has to be familiar with to better understand how best to lean for a given situation.

What is operating “lean of peak”?

As you lean the fuel mixture of an engine, the exhaust gas temperatures (EGT) will climb and eventually reach a peak temperature, after which point continued leaning will result in decreasing exhaust gas temperatures below the peak.

This is referred to as “lean of peak”.

If your aircraft has an EGT indicator that only displays a single point EGT, “lean of peak” refers to leaning the air/fuel mixture to the peak, or the highest, EGT and then continuing to lean the mixture until the desired EGT is reached.

That desired setting could be a particular EGT or an EGT that is x degrees lower than the peak EGT.

For example, if the aircraft you fly has a single-probe EGT gauge (pictured below), the mixture control is pulled back very slowly until the white needle climbs and then starts to drop.

At the peak indication, the highest EGT, the yellow needle is typically set to match that peak (this needle is movable by the pilot and is just used as a tool to visually mark where the peak temperature occurred… moving this needle doesn’t manipulate anything within the engine).

Then, the mixture control is leaned further until the needle drops the desired number of degrees.

You may notice that this particular EGT gauge has no actual numbers indicating the actual temperature. That is because the actual temperatures are not important to us for the leaning process.

When leaning we are typically only interested in when the peak temperature is reached and then how many degrees, relative to that peak, we need to either enrich or lean the mixture.

That is why some EGT gauges, like the one picture above, don’t have those temperature values. Each tick mark is 25 degrees and enables the pilot to operate a specific number of degrees rich or lean relative to peak.

When operating at full rich, there is typically more fuel passing through the cylinder than is necessary for combustion.

There are two reasons why that results in cooler EGTs: the excess fuel acts as a cooling agent and keeps the exhaust gas cool and also the combustion is not very efficient resulting in a cooler burning of the fuel/air mixture.

But, as we pull back on the mixture control and reduce the amount of fuel entering the cylinder, there is less cooling provided by the fuel and the fire burns a bit hotter as the combustion becomes more efficient.

Keep leaning, and eventually the EGT will peak and then start to cool again on the lean side of peak EGT.

Much like when we were too rich, this is because the burning of the fuel/air mixture becomes less efficient and therefore cooler. Lean far enough and there won’t be enough fuel to support combustion at all and the engine will stop.

What is so bad about operating LOP?

Ask experienced pilots about operating LOP and you will typically hear about how ROP results in more detonation margin, cooler exhaust valves, and more power.

The reasoning is because that excess fuel keeps everything cooler and high temperatures, as we’ve all been taught, is the enemy of engine wear. Anything we, as pilots, can do to keep the engine temperatures down is generally a very good thing.

They will tell you that a little bit of extra fuel is cheap insurance against premature wear of those exhaust valves and guides.

Detonation is another major potential problem that we, as pilots, want to avoid at all costs.

You may recall from your training early on that detonation refers to a situation where the fuel/air mixture burns in an uncontrolled manner that results in very high cylinder pressures that can damage both the piston and cylinder walls.

The conventional wisdom at the time that most of these POH’s were written was that hot cylinders (a condition exacerbated by high exhaust gas temperatures) would cause the fuel/air mixture to burn prematurely – before the piston reaches the top of the stroke – and therefore result in damage.

That fear alone is what keeps many pilots from flirting with LOP operations.

The good news (or bad news – depending on your operating philosophy) is that, according to Controlling the Combustion Event, an excellent article from Savvy Aviation and written by Mike Bush, operating LOP actually provides more protection against detonation than when operating at the best power setting which is typically ROP.

The reason is because detonation is most likely to occur when engine pressures are at their highest and earliest. The onslaught of digital engine monitors has resulted in reams of data that were just not available even 20 years ago.

The research Bush has done in analyzing this data shows that the conditions closest to detonation actually occur around 50-100 degrees rich of peak EGT. This is where many POH’s recommend operating the engine.

Therefore, operating LOP affords a bit more cushion in terms of cylinder pressures and temperatures until detonation-rich conditions are met.

It would stand to reason also that exhaust valve wear has more to do with EGT than ROP vs LOP operations. So, whether you’re operating 50 degrees ROP or 50 degrees LOP, the EGT is the same. The only difference is the fuel flow.

What are the benefits to operating LOP?

The main benefit to operating LOP is the fuel savings versus the loss of performance. Naturally, less fuel is being burned at leaner mixture settings which saves money on our fuel bill.

As explained above, there is data now that supports the idea that operating LOP offers more margin against detonation than when operating at the best power setting (typically 50-100 degrees ROP).

Detonation can, quite literally, tear an engine apart.

So, while I would suggest that the POH recommended power and mixture settings provide plenty of margin against detonation, this should not necessarily be a concern when contemplating operating LOP.

Many Pilots Operate LOP Without Realizing It

If you are like me, you learned to fly behind a carbureted, normally aspirated horizontally-opposed aircraft engine and did not even have an EGT gauge to reference. Or, perhaps you did have an EGT gauge but were taught how to lean without it.

The “traditional” leaning procedure goes something like this:

- Set cruise RPM

- Let the aircraft and engine stabilize at cruise for a few minutes

- Lean the mixture slowly

- Listen to the engine

- When it starts to run a bit rough, enrich the mixture until it’s running smoothly again

So, here is my question; if you lean this way, are you running ROP or LOP?

The answer is that it could be either! EGT is not referenced in this leaning technique.

So, depending on the power setting and the other variables affecting the combustion of the fuel, engine roughness is merely indicating that one or more cylinders are not getting enough fuel to support combustion. You have literally blown through ROP/LOP and are now starving the engine of fuel.

In another example, let’s consider the single-probe EGT gauge that was referenced earlier in this article. Because it is installed only on one cylinder, it is possible that all of the other cylinders could be on the lean side of peak EGT by the time peak EGT is indicated on the gauge.

The installation instructions from one EGT gauge manufacturer contains the following:

“Probe location for single probe EGT systems should be…in a cylinder that is determined to be the best representative of the leanest cylinder, or the engine as a whole. Because each engine is unique, this is a major shortcoming of single probe systems.”

Therefore it is very possible that you have been operating LOP frequently and without even knowing it.

Multi-probe EGT’s and Engine Monitors to the Rescue

Fortunately, many of us fly behind much more sophisticated engine monitoring systems that typically include an EGT probe for each cylinder. These monitors very often include a “leaning mode” to make this process much easier with less pilot-workload.

The leaning process might look like this:

- Press the “lean-find” button on the engine monitor

- Lean the mixture until one cylinder’s EGT indication begins to flash on the monitor indicating that peak EGT has been reached

- Adjust the mixture until that cylinder is at the desired temperature relative to peak EGT

These engine monitors also like to know if you’re intending to operate ROP or LOP. That way, it will let you know when the first cylinder peaks (for ROP operations) or the last cylinder peaks (LOP operations).

Operational Considerations

As with any decisions to be made regarding the operation of the aircraft, the Pilot’s Operating Handbook and the engine manufacturer’s Operator’s Manual take precedence over anything seen or heard from other sources.

In fact, I am not advocating one method of leaning over another. What I am doing is trying to provide information that may have not been known when our aircraft’s POH was written.

Remember, our GA fleet is relatively old and many of the POH’s were written long before sophisticated engine monitoring systems were available and there was not much data available to general aviation pilots.

The engine manufacturers update the operator’s manuals much more frequently.

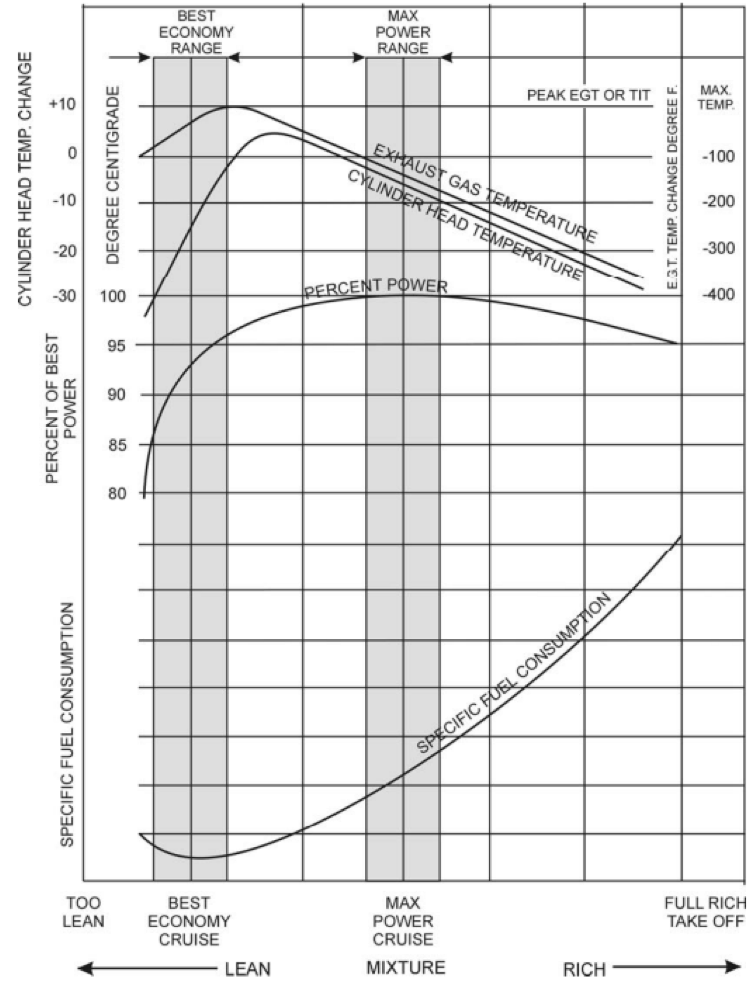

For example, this “representative chart” from Lycoming clearly indicates that best economy power settings could extend from peak EGT to what looks like a bit less than 100 degrees LOP.

Basically, this chart graphically explains how much power is being produced (percent power) along the EGT progression from full rich through a “too lean” setting – meaning, there is not enough fuel being supplied to support combustion.

You can see from the chart that the “best power” shading (the top of the “percent power” curve) occurs between 100 and 175 degrees rich of peak.

Conversely, best economy (the base of the “specific fuel consumption” curve) occurs at peak EGT and continues to about 100 degrees LOP.

So, know what power setting you desire, refer to the POH and the engine’s operator’s manual, and be sure to follow their recommendations. But, you may have reason not to fret LOP operations as much as you may have been taught.