The static air source is likely something we don’t think about very often and even less frequently do we consider the alternate static air source. Static air pressure is required for several instruments that are required for VFR and IFR flight. It is very important to understand what it does, usage limitations, and what to expect when activating the alternate static air source. What is an alternate static air source?

The alternate static air source provides static air pressure to flight instruments in the event that the primary static air source becomes inoperative due to blockage or mechanical failure.

Because you’ve likely never experienced a failure of your altimeter or vertical speed indicator that require static air pressure, it’s easy to take these instruments for granted. This is exactly why the alternate static air source is a system worthy of review.

What is an alternate static air source?

The alternate static air source is a way to get static air pressure to the altimeter, vertical speed indicator, and airspeed indicator when the primary static air pressure source is not usable.

Static air pressure is required for several instruments and any sort of blockage or mechanical failure of the static air system would completely disable those instruments.

When the alternate static source is activated and the primary source for static air pressure is blocked, static air pressure is allowed to enter the system and flow to the flight instruments.

Not all aircraft have a formal alternate static source (I’ll get to why I say “formal” in a moment).

There is no requirement under 14 CFR Part 91.205 for an alternate static air source for either VFR or IFR flight.

Even so, many aircraft have a separate alternate static air source that is activated by opening a valve that will let static air into the system.

If you are flying an aircraft that does not have an alternate static air pressure valve, there is a more informal alternate air source and method to bypass the static air pressure lines: Simply break the glass of the vertical speed indicator.

This will allow static air pressure from the cabin to flow from the front of the instrument back into the static air system and may restore the use of all instruments requiring static air pressure.

What instruments use static air pressure?

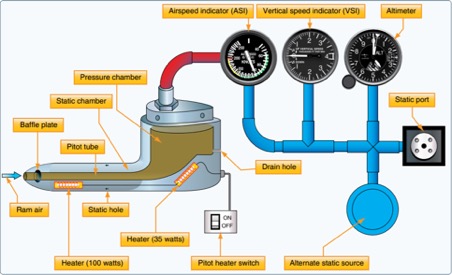

There are three flight instruments that rely upon static air pressure.

Altimeter: The altimeter is the primary user of static air pressure because that is what it does – it measures static air pressure and translates that into the aircraft’s height above a datum (typically sea level).

Vertical Speed Indicator (VSI): The vertical speed indicator measures the change rate of the static air pressure and converts that to a feet-per-minute measurement for the pilot.

Airspeed Indicator: The airspeed indicator uses both ram and static air pressure in order to produce an indicated airspeed for the pilot on the face of that instrument.

Note: If your aircraft has electronic flight instrumentation, you’re not allowed to sleep through this part of the lecture. The only difference is that it is the flight-data-computer that receives static air pressure for the instrumentation rather than each instrument individually.

If the static system is blocked:

Altimeter: The altimeter will freeze at whatever pressure is trapped in the system. If it gets blocked at 9,000’ the altimeter will indicate 9,000’ until the blockage is removed.

Vertical Speed Indicator: The vertical speed indicator will fail to indicate any rate of climb or descent.

Airspeed Indicator: The airspeed indicator will continue to work as long as the pitot tube is not blocked. However, since the static pressure is blocked and not changing with altitude, errors will occur based on the difference between the actual outside static pressure and the pressure in the static system lines when the blockage occurred. The airspeed will read slower at altitudes above the blockage and higher at altitudes below the blockage.

When would you need to use alternate static air?

The short answer is that you should activate the alternate static air source when the primary source of static air pressure is unusable.

Let’s consider some of the reasons why the primary source of static air pressure might not work.

Covered static source: If you’ve recently had your aircraft washed or painted, the static port may have been covered by whomever was doing the work.

Anytime something is covered, there’s a distinct possibility that it may remain covered unless someone remembers to uncover it. An extra-careful preflight inspection after this type of maintenance is a good idea.

One variation of this is “instructor induced” blockage.

It is not unheard of for an instructor, in an effort to test the student’s preflight inspection thoroughness, to place a piece of tape over a static port.

Student pilots, consider yourself warned!

Water in the static system: When washing an aircraft, avoid spraying water under pressure directly at the static port (this is why they are typically covered when washing).

Any water intrusion into the plumbing of the static system could cause a blockage that is not visible during preflight. You may not detect this type of blockage until you are airborne and neither the altimeter or the VSI needles are moving.

In-flight blockage: This is a less common problem that can occur when flying through rain and a water droplet temporarily covers the static port (on a single static port equipped aircraft).

As the drop’s journey down the side of the fuselage stalls over the port, erroneous readings could become evident on the affected instruments. Fortunately, this type of blockage is usually temporary as the rain drop moves away from the port.

While not necessarily a time to consider use of the alternate static pressure source, uncoordinated flight may also result in erroneous instrument indications.

If you slip or skid the aircraft (for more on this, see our article on slipping and skidding turns), exposing the side of the airframe to more direct head-on airflow, that could produce a bit of a pressure change near the static port.

If the port is on the left side of the aircraft and you initiate a left slip, there is now some ram air pressure being introduced into the system through that static port. There would be a descent indicated on the VSI and the altimeter would show a slight decrease in altitude even if the actual altitude is being maintained.

Operating Considerations When Using Alternate Static Air

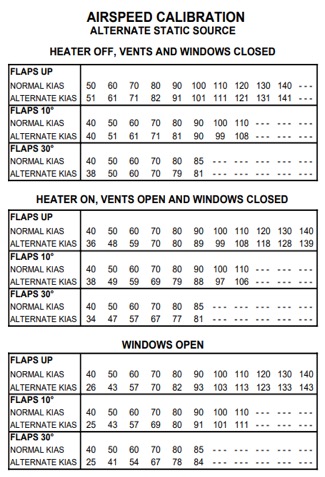

The most important rule to follow when utilizing the alternate static air source is to consult the owner’s manual, POH, or AFM for information and limitations when going to the alternate static source.

The completeness of the information can vary widely. One aircraft’s owner’s manual says, “The most adverse conditions will result in airspeed and altimeter variations of no more than 2 MPH and 15 feet, respectively.”

Other aircraft documentation may include very comprehensive tables.

Your aircraft’s documentation may provide information that should be followed in case the alternate static source is used.

Alternate Static Air Through Breaking Glass of VSI

As was previously mentioned, if your aircraft does not have an alternate static air source and the static system becomes blocked, you may have to break the glass of the VSI.

Why the VSI and not the airspeed indicator or altimeter? Because it’s the cheapest to repair, and the other instruments that use static air pressure are much more important.

When you break the glass on the VSI, static air pressure from the cabin will be allowed to flow back into the static air system and power the remaining instruments.

If, after breaking the glass, your VSI is still operating, be cautioned though. It will indicate backwards; a climb will show as a descent on the VSI and during a descent the VSI will indicate a climb.

This is because the air pressure is moving backwards through the VSI – from the front of the instrument rather than from behind and through the calibrated leak.

How Alternate Static Air Impacts Flight Instruments

Once the alternate air source is selected:

- The airspeed will indicate a speed greater than actual

- The altimeter will indicate a slightly higher altitude

- The VSI will show a climb until it has adjusted to the lower cabin pressure and then it will stabilize

The instruments act a bit differently because the air pressure at the alternate source will be lower than outside the aircraft.

Why is alternate static air at a lower pressure?

The static air pressure inside the aircraft is lower than the static pressure outside thanks to the relative speed of the air around the aircraft.

As we learned early on in our aerodynamic training, air moving quickly has a lower pressure than air moving slowly.

As you move through the air, the air around the aircraft becomes turbulent and has to speed up as soon as the spinner starts to split it so it can meet up again at the tail of the aircraft at the same time as the air a few feet away that does not have to negotiate the airframe.

This creates a low pressure envelope around the airframe.

The air within the cabin is drawn out by the lower pressure surrounding the airframe through airframe leaks and creates lower pressure inside the aircraft. This is why it can be hard to open the little pilot’s window in a Bonanza or Piper Warrior when in flight.

You may be wondering why the static ports are not affected by this lower pressure air surrounding the aircraft. They are!

But, the static ports are placed along the surface of the airframe in places where they lie within the boundary layer.

Air within the boundary layer tends to cling to the surface of the aircraft and not flow as quickly as the air just a few millimeters away. Therefore, it is much closer to the actual ambient static air pressure.

That boundary layer is still moving and does have a slight pressure drop present. That is part of what calibrated airspeed takes into account (which is an entirely different discussion).

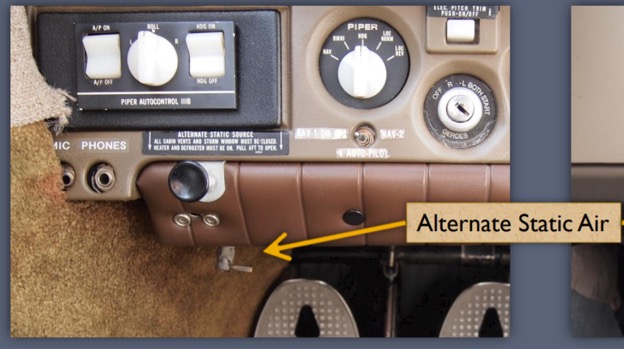

Where is the alternate static air source valve located?

In most general aviation aircraft that are unpressurized, the alternate static air source valve is located behind the instrument panel near the control or it may be the valve itself.

When the control is moved, it directly moves the valve and either opens it or closes it depending on the direction of the control movement.

In pressurized aircraft, the alternate static air source valve is typically located in an area of the fuselage that is outside of the pressure vessel and unpressurized.

In the King Air 200, for example, moving the air source valve on the pilot’s side to the alternate position will draw static air pressure from an unpressurized aft section of the fuselage behind the baggage compartment.

Related Questions

How can the alternate static source be tested?

It is easy to test the alternate static air source. Activate the system with the appropriate control and look for the changes VSI and altimeter. As the lower static air pressure enters the system, the VSI will show a small momentary climb and the altimeter will increase by a few feet. When you shut off the alternate source, the opposite changes will take place.

Does having two static ports help guard against static blockages?

Having a dual static port system will help prevent static blockages as long as the blockage takes place in the lines that are split between the two ports. If the blockage is past where the two lines meet, it makes no difference.